Strategies for Carbon Reduction in Cold drawing of wire: Decarbonization Approaches

"Learn about decarbonization approaches in cold drawing of wire to reduce carbon emissions and contribute to a more sustainable manufacturing industry."

Introduction

Decarbonisation refers to the process of reducing or eliminating carbon emissions from various sectors to mitigate the adverse effects of climate change. The cold drawing of wire sector is a significant contributor to carbon emissions, and therefore, decarbonisation is crucial in this industry. This article aims to explore the importance of decarbonisation in the cold drawing of wire sector, the main sources of carbon emissions, reduction strategies, challenges, and implications of decarbonisation.

What is Decarbonisation in the Cold Drawing of Wire Sector and Why is it Important?

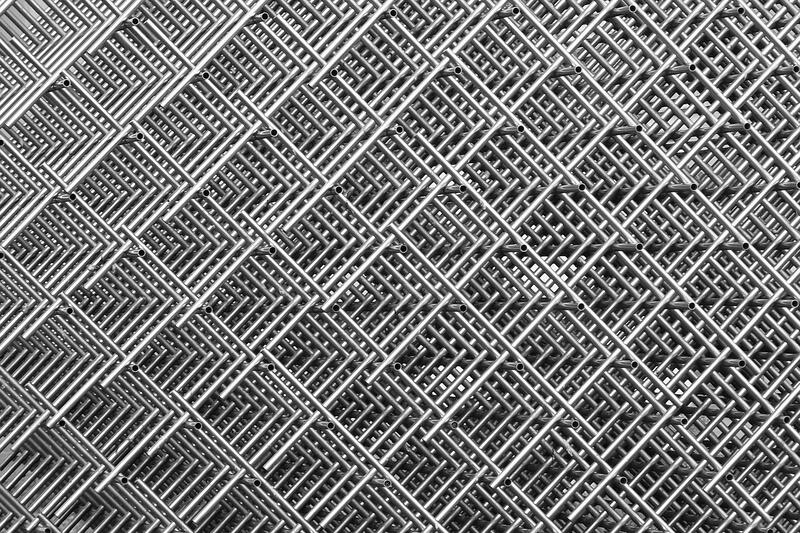

The cold drawing of wire sector involves the production of wire products through the drawing of wire rods through dies to reduce their diameter. The process involves the use of energy-intensive equipment, such as drawing machines, annealing furnaces, and cooling systems, which emit significant amounts of carbon dioxide (CO2) and other greenhouse gases (GHGs). Decarbonisation in this sector involves reducing or eliminating carbon emissions from the production process by adopting cleaner energy sources, improving energy efficiency, and implementing carbon capture and storage technologies.

Decarbonisation is essential in the cold drawing of wire sector for several reasons. Firstly, the sector is a significant contributor to carbon emissions, accounting for about 1.5% of global GHG emissions. Therefore, decarbonisation in this sector can make a significant contribution to global efforts to mitigate climate change. Secondly, the sector is energy-intensive, and reducing carbon emissions can lead to significant cost savings through energy efficiency improvements and the use of renewable energy sources. Thirdly, decarbonisation can enhance the sector's competitiveness by improving its environmental performance and meeting the growing demand for sustainable products.

Main Sources of Carbon Emissions in the Cold Drawing of Wire Sector

The cold drawing of wire sector emits carbon dioxide and other GHGs through various sources, including:

- Energy consumption: The sector is energy-intensive, and the use of fossil fuels, such as coal, oil, and natural gas, to power the production process emits significant amounts of CO2.

- Annealing furnaces: Annealing is a critical process in the production of wire products, and the use of high-temperature furnaces to heat the wire products emits significant amounts of CO2.

- Cooling systems: The production process involves the use of cooling systems to cool the wire products after annealing, and the use of refrigerants, such as hydrofluorocarbons (HFCs), emits significant amounts of GHGs.

- Transportation: The transportation of raw materials and finished products emits significant amounts of CO2 and other GHGs.

Reduction Strategies for Carbon Emissions in the Cold Drawing of Wire Sector

Several strategies can be used to reduce carbon emissions in the cold drawing of wire sector, including:

- Energy efficiency improvements: The sector can reduce carbon emissions by improving energy efficiency through the use of energy-efficient equipment, such as high-efficiency motors, pumps, and compressors, and optimizing production processes to reduce energy consumption.

- Renewable energy sources: The sector can reduce carbon emissions by replacing fossil fuels with renewable energy sources, such as solar, wind, and hydropower.

- Carbon capture and storage: The sector can reduce carbon emissions by capturing CO2 emissions from the production process and storing them in geological formations or using them for enhanced oil recovery.

- Material efficiency improvements: The sector can reduce carbon emissions by improving material efficiency through the use of recycled materials and reducing waste.

- Transportation efficiency: The sector can reduce carbon emissions by improving the efficiency of transportation through the use of low-emission vehicles and optimizing transportation routes.

Challenges Facing Decarbonisation in the Cold Drawing of Wire Sector

Several challenges face decarbonisation in the cold drawing of wire sector, including:

- High capital costs: The adoption of cleaner energy sources and carbon capture and storage technologies requires significant capital investment, which may be challenging for small and medium-sized enterprises.

- Technical limitations: The adoption of some decarbonisation strategies, such as carbon capture and storage, may face technical limitations, such as the availability of suitable geological formations for CO2 storage.

- Regulatory barriers: The lack of supportive policies and regulations may hinder the adoption of decarbonisation strategies, such as renewable energy sources and carbon capture and storage.

- Lack of awareness: The lack of awareness and understanding of decarbonisation strategies and their potential benefits may hinder their adoption by the sector.

Implications of Decarbonisation for the Cold Drawing of Wire Sector

Decarbonisation has several implications for the cold drawing of wire sector, including:

- Improved environmental performance: Decarbonisation can enhance the sector's environmental performance by reducing its carbon footprint and improving its sustainability credentials.

- Cost savings: Decarbonisation can lead to significant cost savings through energy efficiency improvements and the use of renewable energy sources.

- Enhanced competitiveness: Decarbonisation can enhance the sector's competitiveness by meeting the growing demand for sustainable products and improving its environmental performance.

- Innovation opportunities: Decarbonisation can create opportunities for innovation and the development of new technologies and products that meet the sector's decarbonisation goals.

Conclusion

Decarbonisation is crucial in the cold drawing of wire sector to mitigate the adverse effects of climate change, reduce carbon emissions, and enhance the sector's sustainability credentials. The sector can reduce carbon emissions through various strategies, including energy efficiency improvements, the use of renewable energy sources, carbon capture and storage, and material efficiency improvements. However, several challenges, such as high capital costs, technical limitations, regulatory barriers, and lack of awareness, may hinder the adoption of decarbonisation strategies. Decarbonisation can have several implications for the sector, including improved environmental performance, cost savings, enhanced competitiveness, and innovation opportunities.